|

|

||||||||||||||

|

|

||||||||||||||

|

|

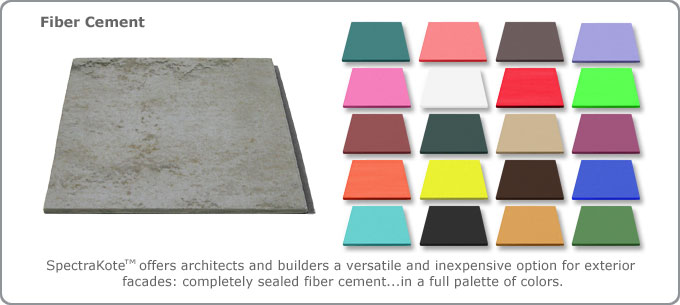

As building materials go, fiber cement has proven itself both versatile and relatively inexpensive over the years. The downside is that in its natural state it looks rather unattractive and requires protection from the elements when used externally. But that hasn't stopped major manufacturers from predicting impressive growth.

However, the manufacturers all face the same problems with their fiber cement products. The formation of fiber cement begins as a water slurry, therefore using any encapsulating sealant requiring heat would cause trapped moisture to migrate and destabilize the surface. Some manufacturers are currently using UV-cured coatings. The problem here is that such products can only be effectively used on flat surfaces. This means sealing one side, turning the product over, then sealing the other side. Finally, the edges are sprayed separately. That's a total of four steps.

With SpectraTechnology you can coat and seal all edges then apply a decorative topcoat as part of the same production line process. Not only does the product emerge ready for packing and shipping, you've used far less energy and a fraction of the time preparing it. How it works - The fiber cement is coated with a specifically formulated paint before moving into a recirculating (invisible) catalyst atmosphere at room temperature (⊇15°C). Here the wet coating absorbs molecules of catalyst and curing begins. Instead of 24 hours, SpectraKote™ takes just eight minutes to cure. Totally. (For a more thorough description of what happens during the SpectraKote process, please check out the Basic Theory and The Process pages.)

More info - If you would like more information about how SpectraTechnology can help you produce fiber cement products more efficiently, just click Contact Us to e-mail your questions. |